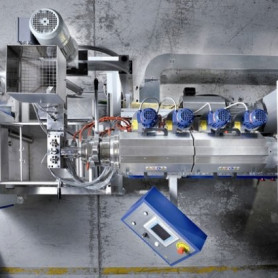

IC, is a plant to produce zippers mono and co-extruded.

The IC machine has been made to produce profiles, bands and zippers in PE, PP and LLDPE-EVA to hermetically seal the bags. The line can be designed with 1 single extruder (monoextrusion) or multiple extruders (max. 3) for coextrusion.

It is composed by:

- plastificator, screenchanger,

- main control unit,

- drawing head,

- cooling tank,

- draw calender,

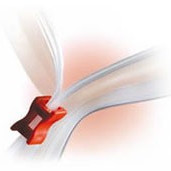

- coupling

- calender

- on request, automatic master batch

- winder.